Car diagnostics need clear signals. Battery cables deliver power pulses. Poor cables distort electrical messages. Distortion leads to false codes. Mechanics face costly misreads daily. Accurate tools reveal hidden issues. Technicians trust reliable connections always. Cable quality impacts signal clarity. Low grade wires cause noise. Noise triggers erroneous diagnostic flags. Repair shops diagnose with scanners. Scanners read voltage fluctuations often. Fluctuations confuse fault algorithms regularly. Clean connections restore accurate data. Professional services replace worn cables. Hughes Motors Corp offers expertise. Clients trust skilled diagnostic staff. Proper maintenance avoids false alerts. Vehicles run smoother after care. Understanding cable health saves money.

Cable Quality and Signal Flow

High grade cables conduct efficiently. Copper strands reduce electrical resistance. Thick insulation shields against interference. Tight connections maintain constant voltage. Stable voltage ensures sensor data. Sensors relay engine performance metrics. Engine control unit processes signals. Precise signals guide fuel injection. Injection timing influences power output. Power output determines vehicle acceleration. Acceleration smoothness reflects cable health. Engine behavior triggers onboard warnings. Warnings appear on diagnostic display. Display codes guide repair decisions. Accurate codes reduce part swaps. Swaps cost time and money. Quality cables prevent costly mistakes. Hughes Motors Corp emphasizes inspection.

False Codes from Poor Connections

Loose terminals allow intermittent contact. Intermittent contact creates signal spikes. Spikes confuse diagnostic algorithms daily. Algorithms interpret spikes as faults. Faults generate error codes frequently. Error codes mislead technicians often. Technicians may replace good parts. Replaced parts increase repair expense. Expense burdens vehicle owners daily. Owners lose confidence in service. Confidence drops when issues persist. Persistent issues indicate hidden problems. Hidden problems often involve wiring. Wiring degradation stems from corrosion. Corrosion forms on connector surfaces. Surfaces obstruct proper electrical flow. Flow interruption triggers warning lights. Warning lights appear during idle. Idle checks reveal inconsistent readings. Hughes Motors Corp resolves errors.

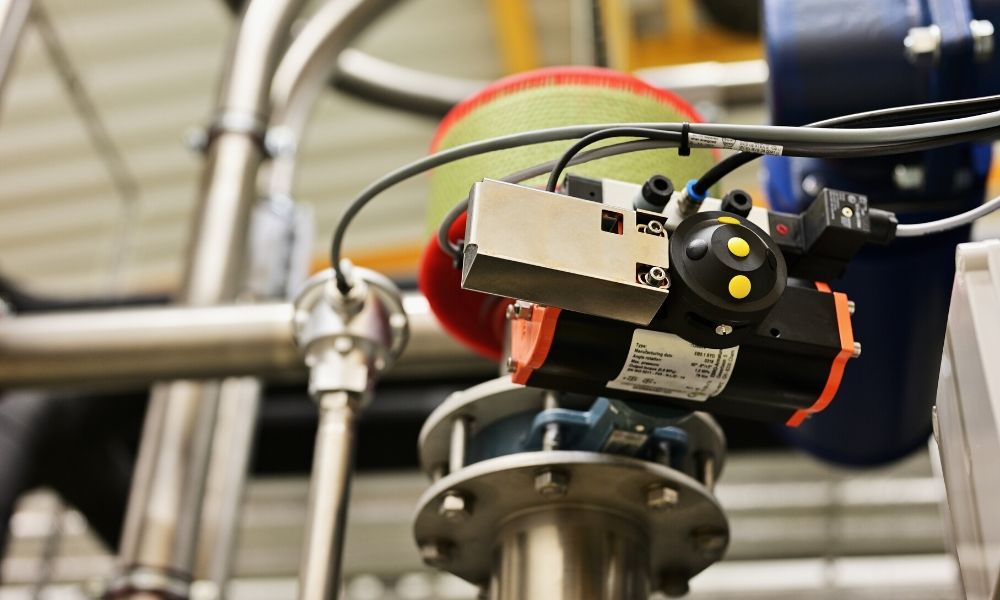

Diagnosing Cable Problems

Technicians start with visual inspection. Inspection looks for frayed insulation. Insulation wear exposes copper strands. Exposed strands cause short circuits. Short circuits distort sensor signals. Sensors send corrupted data streams. Data streams confuse diagnostic readouts. Readouts display misleading fault codes. Fault codes prompt targeted testing. Testing includes multimeter voltage measurements. Voltage measurements confirm cable continuity. Continuity confirms proper conductor path. Path integrity ensures reliable communication. Communication validates engine management functions. Functions operate within calibrated parameters. Parameters shift when cables weaken. Weakening appears during load conditions. Load conditions stress battery connections. Connections benefit from periodic tightening. Hughes Motors Corp performs checks, supporting Auto Repair in Yonkers, NY.

Preventive Practices for Technicians

Technicians schedule regular cable inspections. Inspections include torque verification procedures. Procedures ensure connectors remain tight. Tight connectors prevent voltage irregularities. Irregularities cause diagnostic misinterpretations frequently. Workflow benefits from tool calibration. Scores enhance business reputation locally. Locally shops attract loyal clientele. Clientele appreciates transparent service practices. Practices include documenting condition history. History assists preventive maintenance plans. Hughes Motors Corp champions education.

Leave a Comment